A vane pump is a positive-displacement pump that transfers liquid by the rotating and extending motion of vanes within an eccentric rotor. Widely applied in industrial, automotive, and hydraulic systems, it is known for high efficiency, low pulsation, and stable output, making it an ideal choice for medium to low-pressure hydraulic systems.

NOAH’s VP series double variable displacement vane pump delivers two independent flows from one motor, saving space and powering dual hydraulic circuits.

Explore NOAH’s HVP series medium pressure variable vane pump with shaft clearance compensation and fast load response for stable, efficient hydraulic control.

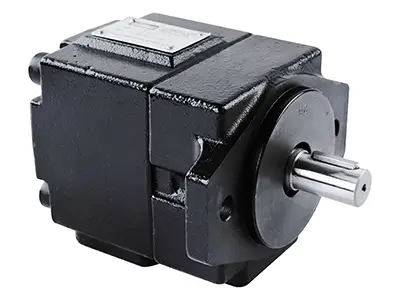

This series of oil pumps offers low noise during operation, smooth running, and excellent wear resistance, making them suitable for use in machine tools and specialized machinery. They feature minimal temperature rise, low horsepower loss, and an integrated automatic pressure compensation design.

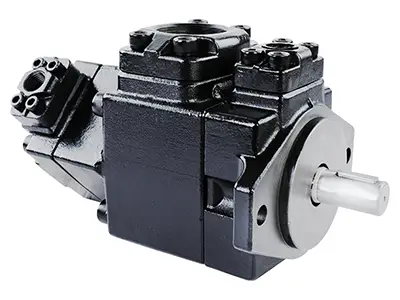

NOAH’s double fixed displacement vane pump delivers high- and low-pressure outputs from one compact, low-noise assembly. Ideal for space-constrained hydraulic systems.

NOAH’s fixed displacement vane pump features high‐flow for dual‐pressure hydraulic circuits on one motor—space‐ and energy‐saving solution.

This pump utilizes a large-flow, low-noise fixed displacement vane pump to form a high-low pressure pump. It can be assembled into a high-low pressure circuit system with a single motor, effectively saving power.

NOAH’s high/low pressure fixed displacement vane pump provides large flow and low noise for dual‐pressure circuits from one compact unit.

This pump is designed as a high-low pressure pump by sharing a common shaft and a single motor. It features low noise, high flow, low cost, and a high volumetric efficiency design.

NOAH’s high pressure fixed displacement vane pump—quiet, efficient, and rated to 21 MPa for reliable high‐pressure hydraulics.

Our high-pressure double vane pumps power two circuits from one inlet—ideal for dual‐actuator hydraulic systems with minimal piping and cost.

This series is composed of two high-pressure vane pumps, designed to provide a dual hydraulic source for hydraulic circuits requiring two simultaneous actions. It features a single suction port, which saves piping, simplifies use, and reduces costs.

Our pump & motor assemblies combine efficient vane pumps with high-performance motors, designed for industrial applications to provide excellent fluid transfer.

First, specific operating requirements must be considered. The pump's performance should match the system's operating parameters. Second, determine the compatibility of the fluid or gas being pumped by the machine in terms of viscosity, chemical composition, etc. The pump's efficiency or energy consumption should also be considered, as these directly affect operating costs. Furthermore, the pump must be able to withstand demanding operating conditions and continuous operation. Finally, you should follow the manufacturer's specifications or consult an expert for long-term performance expectations and maintenance necessities.

Vane pumps use a gas ballast to prevent vapor from condensing inside the pump during the pumping process. This helps maintain the pump's efficiency and service life, especially when dealing with vapors and corrosive gases.

A vacuum gauge is crucial in a vane pump system as it monitors pressure levels and ensures the pump operates within the required vacuum range. It helps maintain optimal performance and safety by providing real-time vacuum measurements.

We've made significant investments in internationally leading precision processing equipment, establishing a truly modern manufacturing platform.

Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.