Widespread application: Widely used as a power source in hydraulic systems across various fields, including automotive, construction machinery, machine tools, mining, woodworking, cold presses, punching machines, and agricultural machinery.

Hydraulic system drive: In the boom joints of construction machinery like excavators and loaders, although hydraulic cylinders are the final actuators, their power source comes from a hydraulic pump driven by a hollow shaft electric motor.

Precision control applications: CNC hydraulic presses utilize servo motors for precise control, making them suitable for jig pressing in the motor, automotive parts, home appliance, and electronics industries, as well as for constant pressure systems and testing systems.

Manufacturing pressing & forming: The hollow shaft electric motor provides stable power for the pressing, forming, shallow drawing, shaping, and press fitting of metal or non-metal parts in manufacturing.

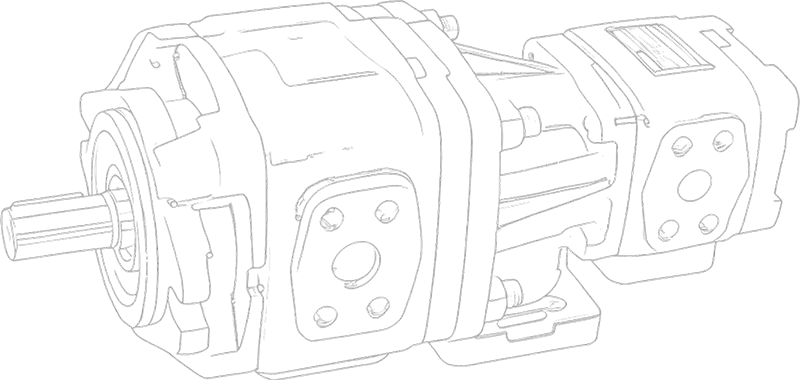

Integration with hydraulic systems: The combination of a hollow shaft electric motor and a hydraulic pump is a critical component in modern industrial automation. They convert electrical energy into hydraulic energy to control and drive various mechanical equipment. This combination enables broad force and speed control, adapting to complex working environments and process requirements, making it an indispensable part of heavy industry and precision manufacturing.