Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.

A vane pump is a positive-displacement pump that transfers liquid by the rotating and extending motion of vanes within an eccentric rotor. Widely applied in industrial, automotive, and hydraulic systems, it is known for high efficiency, low pulsation, and stable output, making it an ideal choice for medium to low-pressure hydraulic systems.

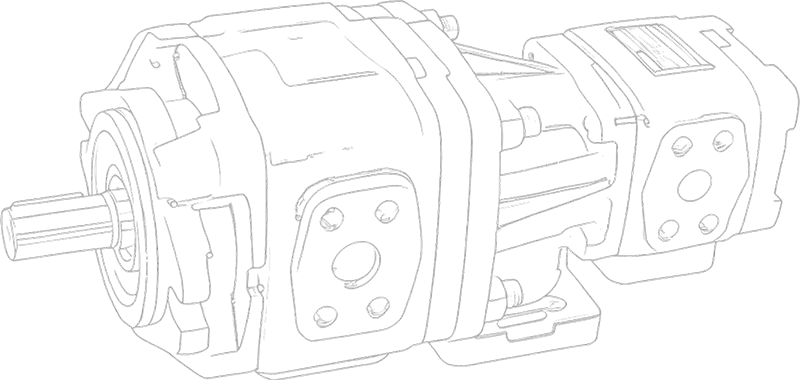

Specifically designed to drive hydraulic pumps, the hollow shaft electric motor plays a crucial role in industrial applications, particularly in hydraulic systems requiring precise control and powerful output.

Noah's hydraulic valves are renowned for their fast response, stable control, and long lifespan. This series of valves is specifically designed for complex hydraulic circuits, applicable to fields such as construction machinery, metallurgical equipment, automated production lines, machine tool equipment, and rubber and plastic machinery. They serve as core components for controlling the direction of hydraulic actuators (e.g., cylinders, motors).

Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.

First, specific operating requirements must be considered. The pump's performance should match the system's operating parameters. Second, determine the compatibility of the fluid or gas being pumped by the machine in terms of viscosity, chemical composition, etc. The pump's efficiency or energy consumption should also be considered, as these directly affect operating costs. Furthermore, the pump must be able to withstand demanding operating conditions and continuous operation. Finally, you should follow the manufacturer's specifications or consult an expert for long-term performance expectations and maintenance necessities.

Vane pumps use a gas ballast to prevent vapor from condensing inside the pump during the pumping process. This helps maintain the pump's efficiency and service life, especially when dealing with vapors and corrosive gases.

A vacuum gauge is crucial in a vane pump system as it monitors pressure levels and ensures the pump operates within the required vacuum range. It helps maintain optimal performance and safety by providing real-time vacuum measurements.

Yes, torque can be adjusted by varying the system pressure or by using motors with adjustable displacement. Your dealer can provide adjustable displacement motors and recommend pressure control valves or regulators to achieve the desired performance.

To extend the cylinder, pull the handle away from the valve. When the handle is released, the valve spring will return to the neutral position, stopping the cylinder. Neutral: Oil circulates from the pump, through the valve, and back to the tank. Work ports are blocked. To retract the cylinder, push the handle towards the valve. When the handle is released, the valve spring will return to the neutral position.

Yes, hydraulic valves may require adjustment to optimize system performance, compensate for wear, or adapt to changing operating conditions.

You can determine if a hydraulic valve is open or closed by checking the actuator position, monitoring changes in flow and pressure within the system, or by inspecting indicator markings on the valve body.