At Noah, our production prowess is defined by large-scale manufacturing, producing 300,000 units per year. We boast profound technical expertise, including seamless hydraulic integration and high-precision casting, alongside unshakeable quality reliability, evidenced by our ISO certification and patent protection. This powerful combination forms the core of our competitive advantage.

Our comprehensive supply chain spans the entire production spectrum, from raw castings to fully integrated hydraulic systems. We excel in customizing non-standard hydraulic solutions and consistently deliver high-quality hydraulic components. With a strategic global footprint in Southeast Asia, Europe, and America, we've solidified our position as an industry leader. Looking ahead, we're committed to expanding our investment in smart production lines, further enhancing our capacity to be a leading domestic alternative in the high-end hydraulic pump and valve market.

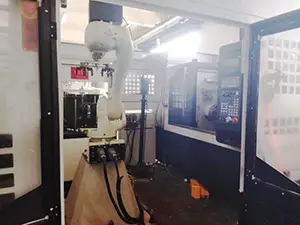

We've made significant investments in internationally leading precision processing equipment, establishing a truly modern manufacturing platform. Our core machining workshops are outfitted with original Japanese MAZAK series CNC turning/milling composite machining centers and MAKINO horizontal machining centers. These elite machines are celebrated for their unparalleled precision, stability, and efficiency. They ensure that even our most complex hydraulic components – like intricate valve bodies, robust pump housings, and vital motor core parts – achieve micrometer-level geometric dimension tolerances and surface finishes that consistently meet the most stringent hydraulic sealing requirements.

| Name | Quantity | Name | Quantity | Name | Quantity |

| Vertical Machining Center | 14 | VMT20 Vertical Lathe | 1 | G18-II Tsugami OD Grinder | 1 |

| YK3120 Gear Hobbing Machine | 1 | 2M8463A Double-Sided Grinder | 1 | CNC Slot Grinder | 3 |

| CK250X500 CNC Slant Bed Lathe | 10 | 640 Drilling-Milling Compound | 8 | 3015 Laser Cutting | 1 |

| Double-End Milling | 2 | CNC Honing | 1 | Wire EDM | 3 |

| CNC Grinding Machine | 5 | Fully Automatic Ultrasonic Cleaning | 1 | Paint Spraying Line | 1 |

VMT20 Vertical Lathe-Milling Compound Center

VMT20 Vertical Lathe-Milling Compound Center 1050 Machining Center

1050 Machining Center RJHJ-1708 CNC Honing Machine

RJHJ-1708 CNC Honing Machine 640 Drill–Milling Compound Center

640 Drill–Milling Compound Center RJHJ-1708 CNC Honing Machine

RJHJ-1708 CNC Honing Machine Fully Automatic Processing Line

Fully Automatic Processing Line Jinhuo Fully Automatic Processing Line

Jinhuo Fully Automatic Processing Line Automatic Painting Line

Automatic Painting Line

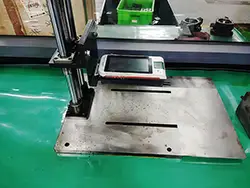

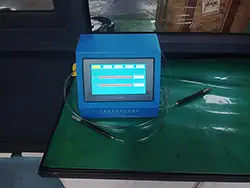

We've engineered state-of-the-art automated motor and power unit assembly lines. These advanced lines seamlessly integrate automatic feeding, precision pressing, intelligent tightening, and real-time online inspection. This holistic approach dramatically elevates assembly precision, consistency, and overall production efficiency, guaranteeing that every motor or power unit leaving our facility delivers exceptional performance and unwavering reliability.

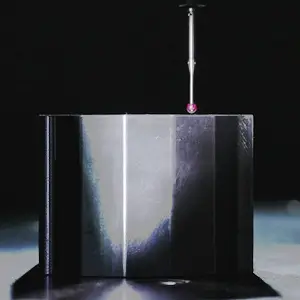

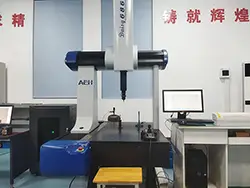

Quality at Noah stems from meticulous control. Our facilities feature advanced Coordinate Measuring Machines (CMMs), allowing us to perform full-dimensional, high-precision inspections of all critical components. This ensures that every part meets the highest standards of our design specifications. Complementing this, our specialized hardness testers rigorously verify material performance, guaranteeing the wear resistance, strength, and longevity of our products right from the source.

| Name | Quantity | Name | Quantity | Name | Quantity |

| Edward CMM | 1 | Pneumatic Internal Diameter Gauge | 1 | Vickers Hardness Tester | 1 |

| DH433CNC Projector | 1 | Runout Gauge | 3 | Rockwell Hardness Tester | 1 |

| Roughness Tester | 1 | Oil Pump Test Bench | 9 | Motor Test Bench | 1 |

| Solenoid Valve Test Bench | 1 | Hydraulic Station Test Bench | 3 |

Vickers Hardness Tester

Vickers Hardness Tester Vickers Hardness Tester

Vickers Hardness Tester Surface Roughness Tester

Surface Roughness Tester Pneumatic Internal Diameter Gauge

Pneumatic Internal Diameter Gauge Coordinate Measuring Machine (CMM)

Coordinate Measuring Machine (CMM) Vision Measuring Machine

Vision Measuring Machine Motor Parameter Tester

Motor Parameter Tester Solenoid Valve Test Bench

Solenoid Valve Test Bench Oil Pump Test Bench

Oil Pump Test Bench Hydraulic Station Test Bench

Hydraulic Station Test BenchOur commitment to product protection encompasses every detail: technical requirements for handling, storage, packaging, safeguarding, and clear labeling. These aspects are meticulously defined within our product technical and management documentation and rigorously controlled under our "Product Protection Control Regulations."

Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.