The HL series internal gear pump utilizes a crescent-shaped internal gear set design. Its core strengths lie in ultra-low pulsation, compact structure, and high pressure resistance. It's specifically engineered for scenarios demanding noise sensitivity, limited space, and precise flow control. These pumps are widely applied in high-end fields such as machine tool hydraulic systems, rubber and plastic machinery, construction machinery, and agricultural machinery, and are particularly well-suited for efficient transfer of low-viscosity media (e.g., synthetic oils, water-glycols).

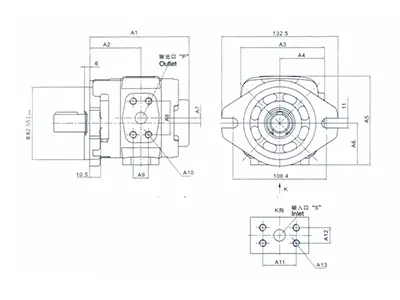

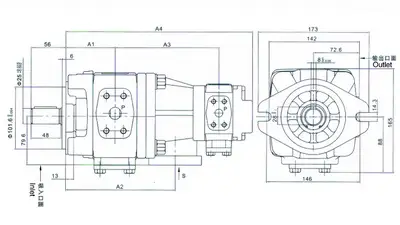

| Pump model | A1 | A2 | A3 | A4 | A5 | A6 | A7 | P | A8 | A9 |

|

|

101.5 | 52.5 | 96 | 51 | 100.6 | 47 | 5.8 | Ø9 | 38.1 | 17.5 |

|

|

105.5 | 54.5 | 96 | 51 | 100.6 | 47 | 5.8 | Ø11 | 38.1 | 17.5 |

|

|

108.5 | 56 | 96 | 51 | 100.6 | 47 | 5.8 | Ø11 | 38.1 | 17.5 |

|

|

113 | 58.25 | 96 | 51 | 100.6 | 47 | 5.8 | Ø13 | 38.1 | 17.5 |

|

|

118 | 60.75 | 96 | 51 | 100.6 | 47 | 6.2 | Ø13 | 38.1 | 17.5 |

|

|

117.5 | 59.25 | 99.6 | 49.8 | 106.6 | 55.8 | 6.2 | Ø13 | 38.1 | 17.5 |

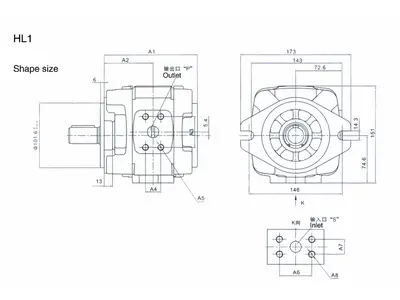

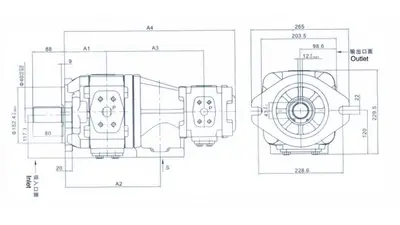

| Pump model | A1 | A2 | P | A3 | A4 | A5 | S | A6 | A7 | A8 |

|

|

139 | 73 | Ø18 | 47.6 | 22.2 | M10 depth 17 | Ø32 | 58.7 | 30.2 | M10 depth 17 |

|

|

146 | 76.5 | Ø18 | 47.6 | 22.2 | M10 depth 17 | Ø32 | 58.7 | 30.2 | M10 depth 17 |

|

|

153 | 80 | Ø20 | 52.4 | 26.2 | M10 depth 17 | Ø32 | 58.7 | 30.2 | M10 depth 17 |

|

|

163 | 85 | Ø20 | 52.4 | 26.2 | M10 depth 17 | Ø32 | 58.7 | 30.2 | M10 depth 17 |

|

|

177 | 92 | Ø20 | 52.4 | 26.2 | M10 depth 17 | Ø32 | 58.7 | 30.2 | M10 depth 17 |

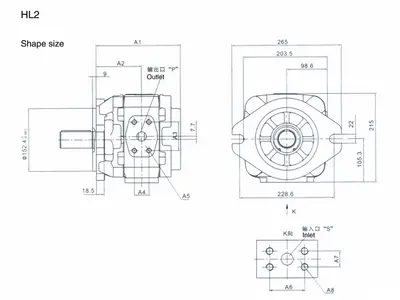

| Pump model | A1 | A2 | P | A3 | A4 | A5 | S | A6 | A7 | A8 |

|

|

204 | 109.5 | Ø32 | 69.9 | 35.7 | M12 depth 20 | Ø50 | 77.8 | 42.9 | M12 depth 20 |

|

|

213 | 114 | Ø32 | 69.9 | 35.7 | M12 depth 20 | Ø50 | 77.8 | 42.9 | M12 depth 20 |

|

|

225 | 120 | Ø38 | 79.4 | 36.5 | M16 depth 25 | Ø63.5 | 88.9 | 50.8 | M12 depth 20 |

|

|

243 | 129 | Ø38 | 79.4 | 36.5 | M16 depth 25 | Ø76 | 106.4 | 61.9 | M16 depth 25 |

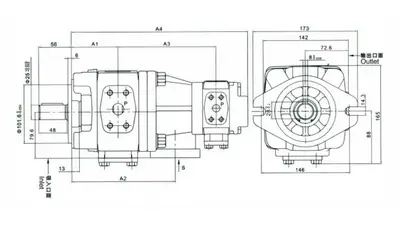

| Pump model | A1 | A2 | Rear pump size | |||||

| 13 | 16 | 20 | ||||||

| A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 164.5 | 165.8 | 297 | 168.5 | 302.5 | 172.5 | 310.5 |

|

|

76.5 | 171.5 | 169.3 | 304 | 172 | 309.5 | 176 | 317.5 |

|

|

80 | 178.5 | 172.8 | 311 | 175.5 | 316.5 | 179.5 | 324.5 |

|

|

85 | 188.5 | 177.8 | 321 | 180.5 | 326.5 | 184.5 | 334.5 |

|

|

92 | 202.5 | 184.8 | 335 | 187.5 | 340.5 | 191.5 | 348.5 |

| Pump model | A1 | A2 | Rear pump size | |||||||||

| 3.5 | 05 | 6.3 | 08 | 10 | ||||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 164.5 | 159 | 281 | 161 | 285 | 162.5 | 288 | 164.8 | 292.5 | 167.3 | 297.5 |

|

|

76.5 | 171.5 | 162.5 | 288 | 164.5 | 292 | 166 | 295 | 168.3 | 299.5 | 170.8 | 304.5 |

|

|

80 | 178.5 | 166 | 295 | 168 | 299 | 169.5 | 302 | 171.8 | 306.5 | 174.3 | 311.5 |

|

|

85 | 188.5 | 171 | 305 | 173 | 309 | 174.5 | 312 | 176.8 | 316.5 | 179.3 | 321.5 |

|

|

92 | 202.5 | 178 | 319 | 180 | 323 | 181.5 | 326 | 183.8 | 330.5 | 186.3 | 335.5 |

| Pump model | A1 | A2 | Rear pump size | |||||||||

| 25 | 32 | 40 | 50 | 63 | ||||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 168 | 175 | 314 | ||||||||

|

|

76.5 | 175 | 178.5 | 321 | 182 | 328 | ||||||

|

|

80 | 182 | 182 | 328 | 185.5 | 335 | 189 | 342 | ||||

|

|

85 | 192 | 187 | 338 | 190.5 | 345 | 194 | 352 | 199 | 362 | ||

|

|

92 | 206 | 194 | 352 | 197.5 | 359 | 201 | 366 | 206 | 376 | 213 | 390 |

An internal gear pump consists of an inner gear and an outer gear, separated by a crescent-shaped divider. The inner gear rotates within the outer gear, trapping fluid in the spaces between the gears and the divider, moving it from the inlet to the outlet.

The maximum speed is 3600 r/min. High speeds are typically suitable for high-viscosity fluids, precision transfer and metering, and oil and gas applications.

The minimum speed is 200 r/min. Low speeds are typically applied in lubrication systems and hydraulic systems.

Regularly flush the system to remove dirt and deposits. Periodically check the cleanliness and viscosity of the lubricant to ensure the lubrication system functions correctly. During daily use, pay attention to any abnormal vibrations and noises. Maintain the gear pump's transmission components and inspect and adjust the safety valve. During gear pump operation, regularly monitor the gear pump's working parameters, including flow, pressure, and temperature.

nternal gear pumps offer numerous advantages, making them a preferred choice in many industries. Key advantages include: high efficiency, self-priming capability, robust structure, wide viscosity range, quiet operation, precise flow control, and low maintenance.

Due to their unique characteristics and advantages, internal gear pumps are widely used across various industries. Common applications include: chemical processing, food and beverage, pharmaceuticals, oil and gas, and pulp and paper.

Choosing the appropriate internal gear pump for your application requires considering factors such as fluid viscosity, flow requirements, temperature conditions, material compatibility, and maintenance needs.

We've made significant investments in internationally leading precision processing equipment, establishing a truly modern manufacturing platform.

Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.