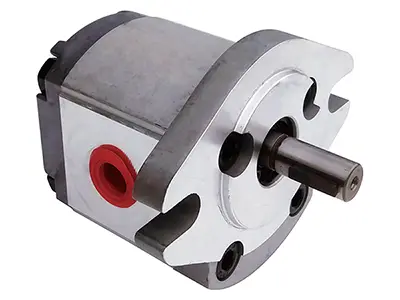

The HGP series external gear pump is a hydraulic power component specifically designed for industrial applications. It features a classic external gear structure, with high reliability, wide adaptability, and long lifespan as its core advantages. Its compact design and precision manufacturing process make it an ideal power source for construction machinery, metallurgical equipment, hydraulic systems, and other fields, especially suitable for complex working conditions requiring medium-to-high pressure and high flow.

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

1 | 210 | 250 | 1800 | 1000 | 4500 | 1 |

|

|

2 | 600 | 4500 | 1.05 | |||

|

|

3 | 600 | 4500 | 1.15 | |||

|

|

4 | 600 | 4500 | 1.18 | |||

|

|

5 | 600 | 3200 | 1.2 | |||

|

|

6 | 600 | 3200 | 1.3 | |||

|

|

7, 8 | 175 | 210 | 600 | 3200 | 1.4 | |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

2 | 210 | 250 | 1800 | 900 | 5000 | 1.69 |

|

|

3 | 850 | 5000 | 1.70 | |||

|

|

4 | 800 | 4500 | 1.71 | |||

|

|

5 | 700 | 3500 | 1.71 | |||

|

|

6 | 700 | 3500 | 1.72 | |||

|

|

7.5 | 600 | 3000 | 1.74 | |||

|

|

9 | 550 | 2500 | 1.74 | |||

|

|

10.5 | 500 | 2000 | 1.74 | |||

|

|

12 | 175 | 210 | 500 | 2000 | 1.76 | |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

6 | 210 | 250 | 1800 | 700 | 3000 | 2.32 |

|

|

8 | 2.40 | |||||

|

|

11 | 600 | 2.53 | ||||

|

|

13 | 2.60 | |||||

|

|

14.3 | 500 | 2.69 | ||||

|

|

16.5 | 2.81 | |||||

|

|

19.2 | 2.92 | |||||

|

|

23 | 3.11 | |||||

|

|

25 | 175 | 210 | 3.20 | |||

|

|

28 | 3.29 | |||||

|

|

30 | 3.38 | |||||

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

1+1 | 210 | 250 | 1800 | 1000 | 4500 | 1 |

|

|

2+2 | 600 | 4500 | 1.05 | |||

|

|

3+3 | 600 | 4500 | 1.15 | |||

|

|

4+4 | 600 | 4500 | 1.18 | |||

|

|

5+5 | 600 | 3200 | 1.2 | |||

|

|

6+6 | 600 | 3200 | 1.3 | |||

|

|

8+8 | 175 | 210 | 600 | 3200 | 1.4 | |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | ||

|

|

2+2 | 210 | 250 | 1800 | 900 | 5000 |

|

|

3+3 | 850 | 5000 | |||

|

|

4+4 | 800 | 4500 | |||

|

|

5+5 | 700 | 3500 | |||

|

|

6+6 | 700 | 3500 | |||

|

|

8+8 | 600 | 3000 | |||

|

|

9+9 | 550 | 2500 | |||

|

|

11+11 | 500 | 2000 | |||

|

|

12+12 | 175 | 210 | 500 | 2000 | |

| Model | A1/A2 | B1/B2 |

|

|

45.8 | 93 |

|

|

47.3 | 96 |

|

|

48.8 | 99 |

|

|

51.3 | 104 |

|

|

53.3 | 107 |

|

|

56.3 | 114 |

|

|

58.3 | 118 |

|

|

61.8 | 125 |

|

|

63.3 | 128 |

|

|

65.3 | 132 |

|

|

67.3 | 136 |

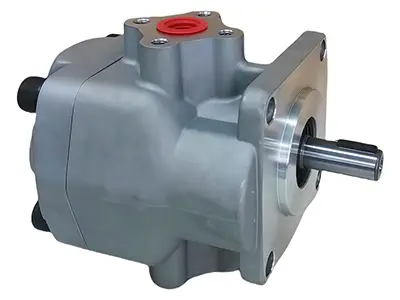

The high-pressure gear pump uses a high-grade aluminum alloy body and is equipped with oil-less bearings and Viton oil seals. It can operate normally in both forward and reverse directions under high temperatures and pressures without leakage, offering superior high-temperature resistance.

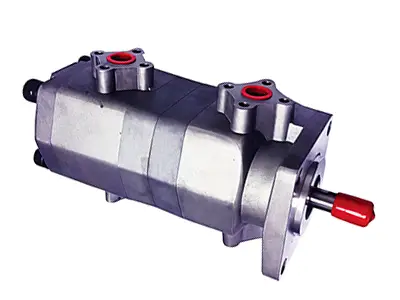

The high-pressure gear pump employs a dual-pump collaborative design, integrating two independent pump bodies. This allows it to simultaneously provide stable flow to multiple hydraulic circuits, optimizing system efficiency and ensuring uniform, continuous fluid delivery, adapting to the precise control needs of multi-circuit hydraulic systems.

Our gear pumps feature an oil-less bearing structure design, ensuring stable operation at pressures above 210 bar. This design also maintains internal lubrication within the pump, guaranteeing minimal wear and a longer service life.

When used with hydraulic motors, electric motors, and similar equipment, we recommend using flange-type gear pumps with a parallel key shaft for greater installation flexibility.

The double high-pressure gear pump utilizes two independent pump chamber designs, capable of providing constant flow to two separate hydraulic circuits. This is particularly suitable for high-load conditions and extreme situations, ensuring smooth operation of the hydraulic system.

For hydraulic systems with limited space, a double pump can be chosen. It integrates two gear pumps into a single unit, occupying less space while operating collaboratively for higher efficiency.

For hydraulic systems with relatively simple functions, where requirements are straightforward and typically involve a single flow output for a specific operation, a single gear pump can be chosen.

We've made significant investments in internationally leading precision processing equipment, establishing a truly modern manufacturing platform.

Please don't hesitate to contact us if you have any questions or concerns about hydraulic components.