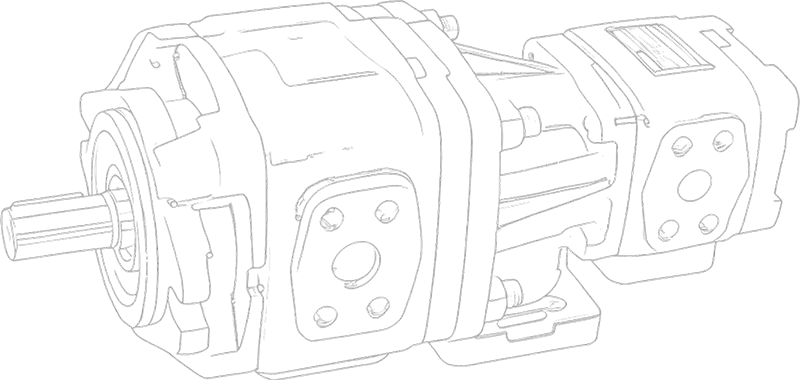

The double pump (tandem pump) consists of two single pumps assembled in series. It features a common inlet port and two outlet ports that can supply two independent circuits. Various displacements can be achieved by combining different pump series.

| Pump model | A1 | A2 | Rear pump size | |||||

| 13 | 16 | 20 | ||||||

| A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 164.5 | 165.8 | 297 | 168.5 | 302.5 | 172.5 | 310.5 |

|

|

76.5 | 171.5 | 169.3 | 304 | 172 | 309.5 | 176 | 317.5 |

|

|

80 | 178.5 | 172.8 | 311 | 175.5 | 316.5 | 179.5 | 324.5 |

|

|

85 | 188.5 | 177.8 | 321 | 180.5 | 326.5 | 184.5 | 334.5 |

|

|

92 | 202.5 | 184.8 | 335 | 187.5 | 340.5 | 191.5 | 348.5 |

| Pump model | A1 | A2 | Rear pump size | |||||||||

| 3.5 | 05 | 6.3 | 08 | 10 | ||||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 164.5 | 159 | 281 | 161 | 285 | 162.5 | 288 | 164.8 | 292.5 | 167.3 | 297.5 |

|

|

76.5 | 171.5 | 162.5 | 288 | 164.5 | 292 | 166 | 295 | 168.3 | 299.5 | 170.8 | 304.5 |

|

|

80 | 178.5 | 166 | 295 | 168 | 299 | 169.5 | 302 | 171.8 | 306.5 | 174.3 | 311.5 |

|

|

85 | 188.5 | 171 | 305 | 173 | 309 | 174.5 | 312 | 176.8 | 316.5 | 179.3 | 321.5 |

|

|

92 | 202.5 | 178 | 319 | 180 | 323 | 181.5 | 326 | 183.8 | 330.5 | 186.3 | 335.5 |

| Pump model | A1 | A2 | Rear pump size | |||||||||

| 25 | 32 | 40 | 50 | 63 | ||||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

73 | 168 | 175 | 314 | ||||||||

|

|

76.5 | 175 | 178.5 | 321 | 182 | 328 | ||||||

|

|

80 | 182 | 182 | 328 | 185.5 | 335 | 189 | 342 | ||||

|

|

85 | 192 | 187 | 338 | 190.5 | 345 | 194 | 352 | 199 | 362 | ||

|

|

92 | 206 | 194 | 352 | 197.5 | 359 | 201 | 366 | 206 | 376 | 213 | 390 |

| Pump model | A1 | A2 | Rear pump size | |||||||||

| 25 | 32 | 40 | 50 | 63 | ||||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

109.5 | 249.5 | 241.5 | 417 | 245 | 424 | 248.5 | 431 | 253.5 | 441 | 260.5 | 455 |

|

|

114 | 258.5 | 246 | 426 | 249.5 | 433 | 253 | 440 | 258 | 450 | 265 | 464 |

|

|

120 | 270.5 | 252 | 438 | 255.5 | 445 | 259 | 452 | 264 | 462 | 271 | 476 |

|

|

129 | 288.5 | 261 | 456 | 264.5 | 463 | 268 | 470 | 273 | 480 | 280 | 494 |

| Pump model | A1 | A2 | Rear pump size | |||||||

| 80 | 100 | 125 | 160 | |||||||

| A3 | A4 | A3 | A4 | A3 | A4 | A3 | A4 | |||

|

|

109.5 | 249.5 | 270 | 474 | ||||||

|

|

114 | 258.5 | 274.5 | 483 | 279 | 492 | ||||

|

|

120 | 270.5 | 280.5 | 495 | 285 | 504 | 291 | 516 | ||

|

|

129 | 288.5 | 289.5 | 513 | 294 | 522 | 300 | 534 | 309 | 552 |

Regularly flush the system to remove dirt and deposits. Periodically check the cleanliness and viscosity of the lubricant to ensure the lubrication system functions correctly. During daily use, pay attention to any abnormal vibrations and noises. Maintain the gear pump's transmission components and inspect and adjust the safety valve. During gear pump operation, regularly monitor the gear pump's working parameters, including flow, pressure, and temperature.

nternal gear pumps offer numerous advantages, making them a preferred choice in many industries. Key advantages include: high efficiency, self-priming capability, robust structure, wide viscosity range, quiet operation, precise flow control, and low maintenance.

Due to their unique characteristics and advantages, internal gear pumps are widely used across various industries. Common applications include: chemical processing, food and beverage, pharmaceuticals, oil and gas, and pulp and paper.