| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

1 | 210 | 250 | 1800 | 1000 | 4500 | 1 |

|

|

2 | 210 | 250 | 1800 | 600 | 4500 | 1.05 |

|

|

3 | 210 | 250 | 1800 | 600 | 4500 | 1.15 |

|

|

4 | 210 | 250 | 1800 | 600 | 4500 | 1.18 |

|

|

5 | 210 | 250 | 1800 | 600 | 3200 | 1.2 |

|

|

6 | 210 | 250 | 1800 | 600 | 3200 | 1.3 |

|

|

7, 8 | 175 | 210 | 1800 | 600 | 3200 | 1.4 |

| Model | A (mm) | B (mm) | Inlet (suction port) | Outlet (pressure port) |

|

|

69.5 | 33.5 | 3/8''PT | 3/8''PT |

|

|

72 | 34.8 | 3/8''PT | 3/8''PT |

|

|

77.5 | 37.5 | 3/8''PT | 3/8''PT |

|

|

79.5 | 38.5 | 3/8''PT | 3/8''PT |

|

|

83.5 | 40.5 | 3/8''PT | 3/8''PT |

|

|

87.5 | 42.5 | 3/8''PT | 3/8''PT |

|

|

93.5 | 45.5 | 1/2''PT | 3/8''PT |

| Model name |

|

| Mounting type | L: foot mounting F: flange mounting |

| Displacement (cc/rev) |

1: 1

2: 2

3: 3

4: 4

5: 5

6: 6

8: 8

|

| Rotation direction | R: clockwise L: counter-clockwise |

| Drive shaft type | X: parallel key shaft Y: spline shaft |

| Flange type | 2B: SAE 2-bolt 4BD: DIN 4-bolt 4DE: European 4-bolt |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

2 | 210 | 250 | 1800 | 900 | 5000 | 1.69 |

|

|

3 | 210 | 250 | 1800 | 850 | 5000 | 1.7 |

|

|

4 | 210 | 250 | 1800 | 800 | 4500 | 1.71 |

|

|

5 | 210 | 250 | 1800 | 700 | 3500 | 1.71 |

|

|

6 | 210 | 250 | 1800 | 700 | 3500 | 1.72 |

|

|

7.5 | 210 | 250 | 1800 | 600 | 3000 | 1.74 |

|

|

9 | 210 | 250 | 1800 | 550 | 2500 | 1.74 |

|

|

10.5 | 210 | 250 | 1800 | 500 | 2000 | 1.74 |

|

|

12 | 175 | 210 | 1800 | 500 | 2000 | 1.76 |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

6 | 210 | 250 | 1800 | 700 | 3000 | 2.32 |

|

|

8 | 210 | 250 | 1800 | 700 | 3000 | 2.4 |

|

|

11 | 210 | 250 | 1800 | 600 | 3000 | 2.53 |

|

|

13 | 210 | 250 | 1800 | 600 | 3000 | 2.6 |

|

|

14.3 | 210 | 250 | 1800 | 500 | 3000 | 2.69 |

|

|

16.5 | 210 | 250 | 1800 | 500 | 3000 | 2.81 |

|

|

19.2 | 210 | 250 | 1800 | 500 | 3000 | 2.92 |

|

|

23 | 210 | 250 | 1800 | 500 | 3000 | 3.11 |

|

|

25 | 175 | 210 | 1800 | 500 | 3000 | 3.2 |

|

|

28 | 175 | 210 | 1800 | 500 | 3000 | 3.29 |

|

|

30 | 175 | 210 | 1800 | 500 | 3000 | 3.38 |

| Model | A (mm) | B (mm) | Inlet (suction port) | Outlet (pressure port) |

|

|

97.4 | 46.7 | 3/4''PT | 1/2''PT |

|

|

99 | 47.5 | 3/4''PT | 1/2''PT |

|

|

101 | 48.5 | 3/4''PT | 1/2''PT |

|

|

105 | 50 | 3/4''PT | 1/2''PT |

|

|

109 | 51.5 | 3/4''PT | 1/2''PT |

|

|

113 | 54 | 3/4''PT | 1/2''PT |

|

|

117 | 56 | 3/4''PT | 1/2''PT |

|

|

123 | 59 | 3/4''PT | 1/2''PT |

|

|

127 | 61 | 3/4''PT | 1/2''PT |

|

|

134 | 65 | 3/4''PT | 1/2''PT |

|

|

137 | 66 | 1''PT | 3/4''PT |

|

|

141 | 68 | 1''PT | 3/4''PT |

|

|

145 | 70 | 1''PT | 3/4''PT |

| Model name |

|

| Mounting type | L: foot mounting F: flange mounting |

| Displacement (cc/rev) |

6: 6

8: 8

11: 11

13: 13

14: 14

17: 17

19: 19

23: 23

25: 25

28: 28

30: 30

|

| Rotation direction | R: clockwise L: counter-clockwise |

| Drive shaft type | X: parallel key shaft Y: spline shaft |

| Flange type | SAE 2-bolt |

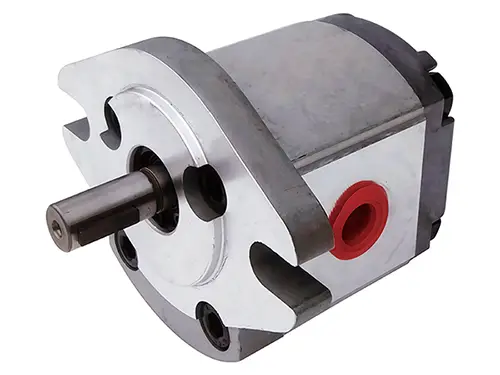

The high-pressure gear pump uses a high-grade aluminum alloy body and is equipped with oil-less bearings and Viton oil seals. It can operate normally in both forward and reverse directions under high temperatures and pressures without leakage, offering superior high-temperature resistance.

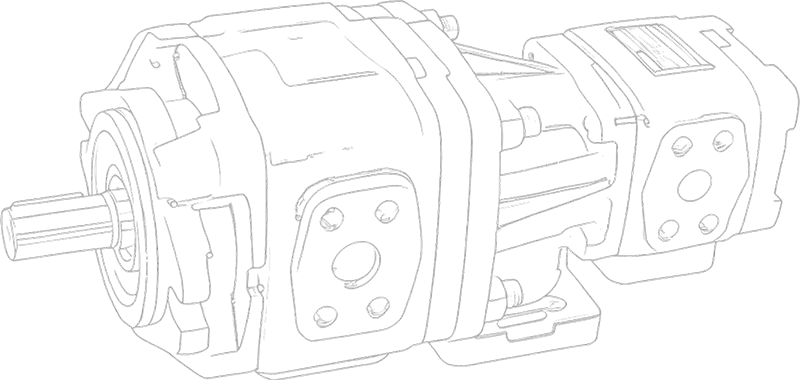

The high-pressure gear pump employs a dual-pump collaborative design, integrating two independent pump bodies. This allows it to simultaneously provide stable flow to multiple hydraulic circuits, optimizing system efficiency and ensuring uniform, continuous fluid delivery, adapting to the precise control needs of multi-circuit hydraulic systems.

Our gear pumps feature an oil-less bearing structure design, ensuring stable operation at pressures above 210 bar. This design also maintains internal lubrication within the pump, guaranteeing minimal wear and a longer service life.