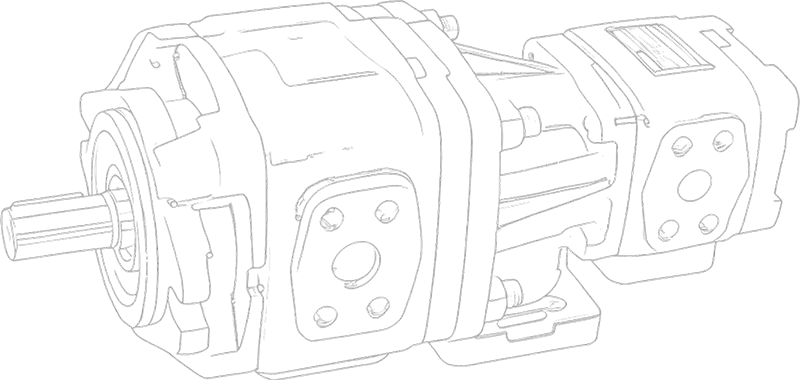

The double high-pressure gear pump utilizes a dual-pump integrated design. It features a high-grade aluminum alloy body, equipped with oilless bearings and Viton oil seals, offering resistance to high temperatures, high speeds, high pressures, and high torque, making it suitable for extreme working conditions.

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | Weight (kg) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | |||

|

|

1+1 | 210 | 250 | 1800 | 1000 | 4500 | 1 |

|

|

2+2 | 210 | 250 | 1800 | 600 | 4500 | 1.05 |

|

|

3+3 | 210 | 250 | 1800 | 600 | 4500 | 1.15 |

|

|

4+4 | 210 | 250 | 1800 | 600 | 4500 | 1.18 |

|

|

5+5 | 210 | 250 | 1800 | 600 | 3200 | 1.2 |

|

|

6+6 | 210 | 250 | 1800 | 600 | 3200 | 1.3 |

|

|

8+8 | 175 | 210 | 1800 | 600 | 3200 | 1.4 |

| Model | Displacement (cc/rev) |

Operating pressure (bar) | Rotation speed (rpm) | |||

| Rated pressure | Peak pressure | Rated | Min. | Max. | ||

|

|

2+2 | 210 | 250 | 1800 | 900 | 5000 |

|

|

3+3 | 210 | 250 | 1800 | 850 | 5000 |

|

|

4+4 | 210 | 250 | 1800 | 800 | 4500 |

|

|

5+5 | 210 | 250 | 1800 | 700 | 3500 |

|

|

6+6 | 210 | 250 | 1800 | 700 | 3500 |

|

|

8+8 | 210 | 250 | 1800 | 600 | 3000 |

|

|

9+9 | 210 | 250 | 1800 | 550 | 2500 |

|

|

11+11 | 210 | 250 | 1800 | 500 | 2000 |

|

|

12+12 | 175 | 210 | 1800 | 500 | 2000 |

| Model | A1/A2 | B1/B2 |

|

|

45.8 | 93 |

|

|

47.3 | 96 |

|

|

48.8 | 99 |

|

|

51.3 | 104 |

|

|

53.3 | 107 |

|

|

56.3 | 114 |

|

|

58.3 | 118 |

|

|

61.8 | 125 |

|

|

63.3 | 128 |

|

|

65.3 | 132 |

|

|

67.3 | 136 |

| Model name |

|

| Mounting type | L: foot mounting F: flange mounting |

| Rotation direction | R: clockwise L: counter-clockwise |

| Drive shaft type | X: parallel key shaft Y: spline shaft Z: taper shaft |

| Flange type | 2B: SAE 2-bolt 4BD: DIN 4-bolt |

When used with hydraulic motors, electric motors, and similar equipment, we recommend using flange-type gear pumps with a parallel key shaft for greater installation flexibility.

The double high-pressure gear pump utilizes two independent pump chamber designs, capable of providing constant flow to two separate hydraulic circuits. This is particularly suitable for high-load conditions and extreme situations, ensuring smooth operation of the hydraulic system.

For hydraulic systems with limited space, a double pump can be chosen. It integrates two gear pumps into a single unit, occupying less space while operating collaboratively for higher efficiency.